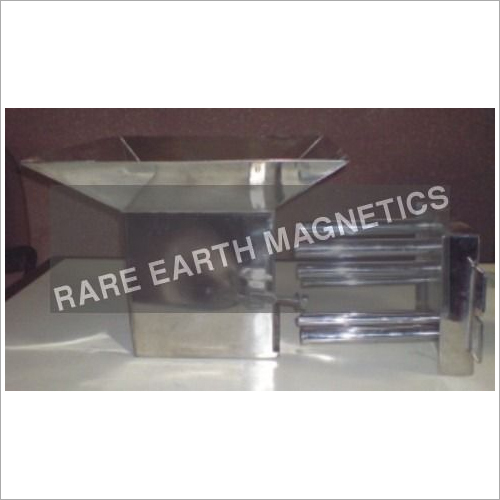

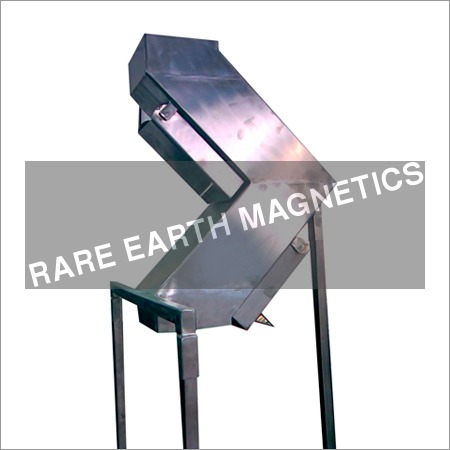

Chute Magnetic Separators

Chute Magnetic Separators Specification

- Power Supply

- Electric

- Application

- Iron Separation, Material Purification

- Surface Finish

- Polished / Brushed

- Frequency

- 50/60 Hz

- Material

- Stainless Steel 304/316, Magnetic plates inside

- Composite

- Magnets, Stainless Steel

- Product Type

- Chute Magnetic Separator

- Magnet Category

- Industrial Magnetic Separator

- Magnet Type

- Permanent Magnet

- Shape

- Rectangular (Chute Type)

- Size Range

- Standard & Custom Sizes

- Color

- Silver / Metallic Finish

- Usage & Applications

- Cement, Food, Pharma, Mining, Chemicals, Plastics, Bulk Material Handling

- Capacity

- Up to 5 TPH

Chute Magnetic Separators Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Supply Ability

- Piece

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- North America, Middle East, Western Europe, Africa, Central America, South America, Asia, Australia

- Main Domestic Market

- All India

About Chute Magnetic Separators

Leveraging on our wide industry experience, we manufacture, export and supply an extensive range of Chute Type Magnetic Separators. These separators are extensively used in various processing industries to remove various kinds of ferrous and para-magnetic materials from process lines to prevent product contamination and damage to machinery. Manufactured under the strict vigilance of our adroit technocrats, offered Chute Type Magnetic Separators are available with us in various technical specifications at highly competitive price.

Features:

-

Robust construction

-

Longer service life

-

High operational fluency

-

Application specific design

Optimized Iron Separation for Diverse Industries

Our Chute Magnetic Separator is engineered to deliver high-efficiency iron extraction in industrial settings ranging from bulk material handling to the food and pharmaceutical sectors. Its rugged stainless steel construction and industrial-grade permanent magnets guarantee consistent performance and durability, making it an indispensable asset in modern purification processes.

Versatile Design for Standard and Custom Operations

Whether you require a standard rectangular chute or a custom-sized separator, our solutions adapt to various operational scales. The polished metallic finish allows for easy cleaning and hygiene maintenance, making them a preferred choice for sensitive industries. Flexible capacity up to 5 TPH fits both high-output and small-scale applications.

FAQs of Chute Magnetic Separators:

Q: How does the Chute Magnetic Separator work for iron separation?

A: The separator operates by channeling bulk material through a rectangular chute lined with powerful permanent magnetic plates. As the material passes through, ferrous particles are attracted to the magnets and separated from the non-magnetic stream, ensuring purified output.Q: What materials and industries can benefit from using this magnetic separator?

A: This separator is suitable for various materials handled in the cement, food, pharmaceutical, mining, chemical, and plastics industries. It is specifically designed for bulk material purification, protecting both products and equipment from ferrous contamination.Q: When should I choose a custom size versus a standard chute magnetic separator?

A: Opt for a custom-size separator when your process involves unique material flow rates, space limitations, or specialized application requirements. Standard sizes are ideal for typical material streams and industry-standard processing setups.Q: Where is this magnetic separator installed within the processing line?

A: The separator is typically positioned at strategic points where bulk materials are transferred, such as feed chutes, conveyors, or discharge outlets, maximizing iron separation at critical process junctures.Q: What is the process for cleaning and maintaining the magnetic plates?

A: Regular cleaning is essential for optimal performance. Magnetic plates inside the chute feature a polished or brushed finish, making them easy to wipe down and ensuring hygienic operation, particularly in food and pharma environments.Q: How does using this separator enhance operational efficiency and product safety?

A: By effectively removing ferrous contaminants, the separator safeguards downstream processing equipment from damage, prevents product defects, and complies with safety standards. This results in improved product quality, reduced downtime, and lower maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Magnetic Separators Category

Liquid Line Magnetic Separator

Minimum Order Quantity : As Per Requirement Piece

Color : Metallic Silver

Size Range : Available from 1 inch to 8 inches pipe diameter

Magnet Grade : N35 / N52

Usage & Applications : Food Processing, Pharmaceuticals, Chemical Industries and Slurry Processing Lines

Material : 304 / 316 Stainless Steel

Industrial Chute Magnetic Separators

Minimum Order Quantity : As Per Requirement Piece

Color : Silver/Metallic with blue and yellow highlighting

Size Range : Available in custom and standard sizes

Magnet Grade : NdFeB (Neodymium) / Ferrite

Usage & Applications : Ideal for bulk material handling, food, chemicals, plastics, minerals, and recycling industries

Material : Stainless Steel Body, Magnetic Core

Hump Magnetic Separator

Minimum Order Quantity : As Per Requirement Piece

Color : Industrial Grey with metallic finish

Size Range : Standard inlet sizes from 6 to 20 (custom sizes available)

Magnet Grade : N35 (Neodymium) / Ceramic Ferrite

Usage & Applications : Food, pharmaceuticals, plastics, chemicals, grain processing, powder handling, bulk material conveying systems

Material : Mild Steel (Body), Stainless Steel (available on request)

Hump Type Separator

Minimum Order Quantity : As Per Requirement Piece

Color : Industrial grey, metallic silver, or as specified

Size Range : Customizable, typically 150 mm to 600 mm inlet/outlet dia

Magnet Grade : N35, N40, N52 (for rare earth options)

Usage & Applications : Food processing, plastic granules, grain cleaning, chemical industries, mining

Material : Mild Steel, Stainless Steel 304/316

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS