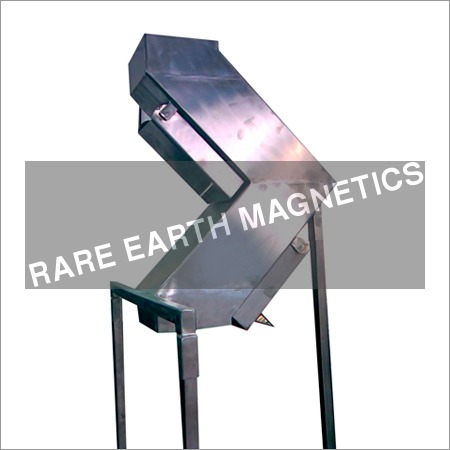

Industrial Chute Magnetic Separators

Industrial Chute Magnetic Separators Specification

- Frequency

- 50/60 Hz

- Composite

- Magnetic Separator with Chute Design

- Surface Finish

- Polished/Brushed Stainless Steel

- Material

- Stainless Steel Body, Magnetic Core

- Power

- Manual/Low Power

- Power Supply

- Electric (if equipped with automation)

- Magnet Grade

- NdFeB (Neodymium) / Ferrite

- Product Type

- Industrial Chute Magnetic Separators

- Magnet Category

- Magnetic Separator

- Magnet Type

- Permanent Magnets

- Shape

- Rectangular/Chute Form

- Size Range

- Available in custom and standard sizes

- Color

- Silver/Metallic with blue and yellow highlighting

- Usage & Applications

- Ideal for bulk material handling, food, chemicals, plastics, minerals, and recycling industries

- Capacity

- Varies as per chute size high throughput

Industrial Chute Magnetic Separators Trade Information

- Payment Terms

- Days after Acceptance (DA), Cheque, Cash Advance (CA)

- Supply Ability

- Piece

- Delivery Time

- Months

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, Middle East, Western Europe, Africa, Central America, Eastern Europe, South America, Asia, North America

- Main Domestic Market

- All India

About Industrial Chute Magnetic Separators

We introduce ourselves as a noteworthy organization betrothed in manufacturing, exporting and supplying Chute Magnetic Separator to our clients. This separator is manufactured using utmost quality basic components and advanced techniques in line with set international quality standards. Provided separator is ideal for removing various kinds of ferrous metal from high-volume dry product that are made to flow in it through a vertical chute. We are offering this Chute Magnetic Separator at an affordable price range to the clients.

Features:

-

High operational fluency

-

Robust construction

-

Precisely engineered

-

Negligible maintenance

Robust Stainless Steel Construction

Built with a high-quality stainless steel body and a secure magnetic core, these industrial chute magnetic separators provide durability, longevity, and resistance to corrosion. The polished or brushed finish not only adds aesthetic appeal but helps maintain sanitary operation, making them perfect for industries with strict cleanliness requirements.

Efficient Magnetic Separation Technology

Fitted with powerful Neodymium (NdFeB) or Ferrite magnets, these separators attract and hold ferrous impurities from flowing bulk materials. The rectangular/chute design is engineered to maximize contact with material streams for optimal separation and minimal material loss, ensuring product purity and equipment protection.

Customizable Solutions for Diverse Applications

With options available for both standard and tailor-made sizes, these chute magnetic separators cater to varied operational requirements. Their adaptability makes them suitable for installation in bulk material handling lines across food, plastics, chemicals, minerals, and recycling sectors, meeting the unique demands of each industry.

FAQs of Industrial Chute Magnetic Separators:

Q: How do industrial chute magnetic separators function in bulk material handling?

A: These separators work by utilizing strong permanent magnets strategically placed within a chute or rectangular housing. As bulk material flows through, the magnetic field captures and retains ferrous contaminants, ensuring cleaner end products and reducing the risk of machinery damage.Q: What are the main applications for these magnetic chute separators?

A: Industrial chute magnetic separators are typically used in the food, chemical, plastic, minerals, and recycling industries, where they ensure product purity by extracting ferrous materials from bulk solids or powders during processing and packaging.Q: When should I choose a custom size magnetic separator over a standard model?

A: A custom size is ideal when you have unique space constraints or specific throughput requirements that standard sizes cannot accommodate. Customization ensures seamless integration into your current material handling line, maximizing efficiency and effectiveness.Q: Where is this equipment most effectively installed within an industrial process?

A: These separators are most effective when installed in material transfer or drop zones, such as at the discharge point of conveyors or hoppers, allowing for immediate removal of unwanted metal before further processing.Q: What is the primary benefit of using NdFeB or Ferrite magnets in these separators?

A: NdFeB (Neodymium) and Ferrite magnets ensure strong, consistent magnetic fields that can capture even fine ferrous particles at high processing speeds. This results in enhanced separation efficiency and greater overall product quality.Q: How is the separator powered and does it require electrical supply?

A: Most models operate manually due to the permanent magnets nature, requiring no electrical input. If equipped with automation for cleaning or operation, a low power electric supply at 50/60 Hz may be needed.Q: What maintenance processes should be followed to optimize performance?

A: Regular cleaning of the magnetic surface, inspection for mechanical wear, and checking the magnetic strength ensure long-term performance. For automated models, periodic evaluation of electrical components is recommended.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Magnetic Separators Category

Liquid Line Magnetic Separator

Minimum Order Quantity : As Per Requirement Piece

Material : 304 / 316 Stainless Steel

Usage & Applications : Food Processing, Pharmaceuticals, Chemical Industries and Slurry Processing Lines

Magnet Category : Permanent Magnets

Capacity : Up to 10,000 ltr/hr (varies by model)

Color : Metallic Silver

Grid Type Magnetic Separator

Minimum Order Quantity : As Per Requirement Piece

Material : Stainless Steel 304/316L, Magnetic Bars

Usage & Applications : Food Processing, Pharmaceuticals, Plastic, Chemical, Ceramic, Mining

Magnet Category : Other, Rare Earth/Neodymium/Ferrite Options

Capacity : Up to 50 TPH (Varies by Design/Size)

Color : Metallic Silver (Stainless Steel Finish)

Hump Magnetic Separator

Minimum Order Quantity : As Per Requirement Piece

Material : Mild Steel (Body), Stainless Steel (available on request)

Usage & Applications : Food, pharmaceuticals, plastics, chemicals, grain processing, powder handling, bulk material conveying systems

Magnet Category : Other, Industrial Plate Magnet

Capacity : 50 kg/hr upto 5000 kg/hr based on model

Color : Industrial Grey with metallic finish

Hump Type Separator

Minimum Order Quantity : As Per Requirement Piece

Material : Mild Steel, Stainless Steel 304/316

Usage & Applications : Food processing, plastic granules, grain cleaning, chemical industries, mining

Magnet Category : Other, Rare Earth or Ferrite Magnets (as per order)

Capacity : Upto 50 TPH (tons per hour) depending on size and application

Color : Industrial grey, metallic silver, or as specified

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS