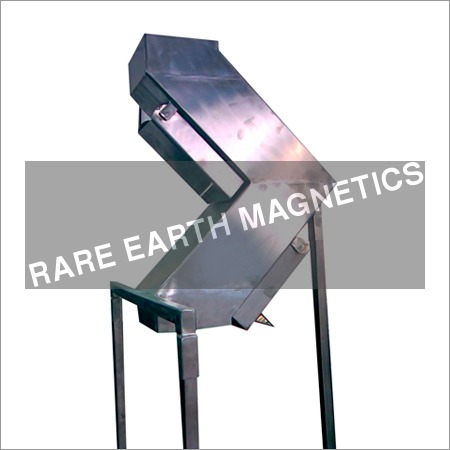

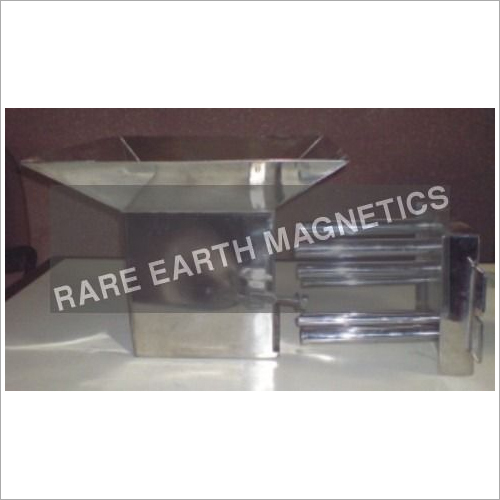

Hump Type Separator

Hump Type Separator Specification

- Frequency

- 50 Hz or 60 Hz

- Magnet Grade

- N35, N40, N52 (for rare earth options)

- Material

- Mild Steel, Stainless Steel 304/316

- Composite

- Mild Steel or Stainless Steel (customer specified)

- Power Supply

- Not required for magnetic function

- Product Type

- Magnetic Separator

- Magnet Category

- Rare Earth or Ferrite Magnets (as per order)

- Magnet Type

- High intensity permanent magnets

- Shape

- Hump Type (double plate with angular offset)

- Size Range

- Customizable, typically 150 mm to 600 mm inlet/outlet dia

- Weight

- Varies as per model and size (standard models from 50 kg upwards)

- Color

- Industrial grey, metallic silver, or as specified

- Usage & Applications

- Food processing, plastic granules, grain cleaning, chemical industries, mining

- Capacity

- Upto 50 TPH (tons per hour) depending on size and application

Hump Type Separator Trade Information

- Payment Terms

- Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- Piece

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Hump Type Separator

Driven by technical excellence, we are counted as the topmost manufacturer, exporter and supplier of an excellent quality range of Hump Type Separator. Offered separators are used to remove various kinds of ferrous contaminants such as iron nuts, bolts, wire, banding and many more from conveyed materials. Proposed separator is manufactured in line with international quality standards using utmost quality components and progressive techniques. Proposed Hump Type Separator is available for clients in several technical specifications at most competitive prices.

Features:

-

Optimum performance

-

Corrosion resistance

-

High operational fluency

-

Longer service life

Custom-Engineered for Your Needs

Our Hump Type Separators are engineered to meet specific application requirements, offering flexibility in material, size, magnet type, and performance. Whether you need mild steel or stainless steel, rare earth or ferrite magnets, each unit is customized for optimal efficiency and durability in demanding environments.

Effortless, Reliable Magnetic Separation

Designed for high-intensity separation, these separators operate without the need for electrical power due to their permanent magnet technology. The double-plate hump construction maximizes separation capability even at high throughput, ensuring clean output for food, plastics, chemicals, and mining industries.

FAQs of Hump Type Separator:

Q: How does a Hump Type Separator work in industrial settings?

A: A Hump Type Separator uses high-intensity permanent magnets arranged in a double-plate, angular offset formation. As material flows through, ferrous contaminants are attracted and separated, ensuring maximum product purity without interrupting the process flow.Q: What materials can be separated using this hump type magnetic separator?

A: This separator effectively removes ferrous particles from free-flowing materials such as grains, plastic granules, chemicals, and various powders or bulk solids, making it ideal for food, plastic, mining, and chemical processing industries.Q: When should I specify the stainless steel or mild steel option for construction?

A: Choose stainless steel (304/316) for applications involving corrosive or food-grade materials, as it offers superior resistance and hygiene. Mild steel is suitable for standard industrial or non-food processing environments.Q: Where can these separators be installed in a processing line?

A: Hump Type Separators are typically installed at points where materials flow vertically, such as in gravity-fed ducts or chutes, before packaging or processing stations, to ensure effective trapping of ferrous contaminants.Q: What is the process for customizing the size and magnet type?

A: Upon placing an order, customers can specify the desired inlet/outlet diameter (150 mm600 mm) and choose between rare earth (grades N35, N40, N52) or ferrite magnets, as well as the color and material, ensuring seamless integration into existing setups.Q: How does using this separator benefit food, plastic, or grain processing applications?

A: By efficiently removing ferrous contaminants, these separators ensure product purity, reduce equipment wear, and enhance overall process safetykey requirements in food, plastic, grain, and related industries.Q: What are the usage and maintenance requirements for the magnetic function?

A: Since the separator uses permanent magnets, no electrical power is required for the magnetic function. Periodic manual cleaning is recommended to remove accumulated ferrous debris and maintain peak performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Magnetic Separators Category

Liquid Line Magnetic Separator

Minimum Order Quantity : As Per Requirement Piece

Color : Metallic Silver

Usage & Applications : Food Processing, Pharmaceuticals, Chemical Industries and Slurry Processing Lines

Product Type : Other, Liquid Line Magnetic Separator

Capacity : Up to 10,000 ltr/hr (varies by model)

Magnet Type : Other, Rare Earth / Ferrite Magnetic Tubes

Grid Type Magnetic Separator

Minimum Order Quantity : As Per Requirement Piece

Color : Metallic Silver (Stainless Steel Finish)

Usage & Applications : Food Processing, Pharmaceuticals, Plastic, Chemical, Ceramic, Mining

Product Type : Other, Grid Type Magnetic Separator

Capacity : Up to 50 TPH (Varies by Design/Size)

Magnet Type : Other, Permanent Magnet

Hump Magnetic Separator

Minimum Order Quantity : As Per Requirement Piece

Color : Industrial Grey with metallic finish

Usage & Applications : Food, pharmaceuticals, plastics, chemicals, grain processing, powder handling, bulk material conveying systems

Product Type : Other, Magnetic Separator

Capacity : 50 kg/hr upto 5000 kg/hr based on model

Magnet Type : Other, Permanent Magnets (Ferrite or Rare Earth)

Chute Magnetic Separators

Minimum Order Quantity : As Per Requirement Piece

Color : Silver / Metallic Finish

Usage & Applications : Cement, Food, Pharma, Mining, Chemicals, Plastics, Bulk Material Handling

Product Type : Other, Chute Magnetic Separator

Capacity : Up to 5 TPH

Magnet Type : Other, Permanent Magnet

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS