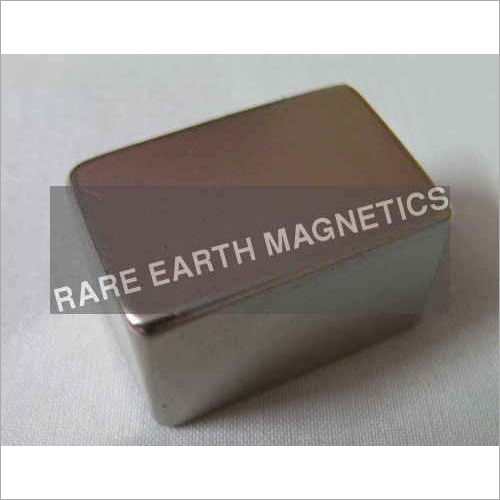

Rare Earth Plate Magnets

MOQ : As Per Requirement Piece

Rare Earth Plate Magnets Specification

- Power Supply

- Not Required

- Surface Finish

- Polished Stainless Steel

- Composite

- Solid Plate Magnet with Rare Earth magnet embedded

- Product Type

- Plate Magnet

- Magnet Category

- Permanent Magnet

- Magnet Type

- Rare Earth (Neodymium) Magnet

- Shape

- Rectangular Plate

- Size Range

- Customizable; standard width from 100 mm to 1000 mm

- Weight

- Depends on size; typically ranges from 10 kg upwards

- Color

- Metallic Grey / Silver

- Usage & Applications

- Used above conveyors, chutes, or hoppers for magnetic separation

- Capacity

- Handles large flow rates depending on application and installation size

Rare Earth Plate Magnets Trade Information

- Payment Terms

- Cash Advance (CA), Days after Acceptance (DA), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- Piece

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, South America, Western Europe, Africa, Central America, Asia

About Rare Earth Plate Magnets

Rare Earth Magnets (NdFeB & SmCo, Sintered as well as bonded)

We sell all kinds of Rare Earth Magnets in different shapes and sizes in grades N35 to N50 for working temperature of upto 80 deg C and H,SH & UH grade for high temperature upto 250 deg C. We also supply SmCo magnets (SmCo5 and Sm2Co17 grades )that can be used at 350 deg C.

Robust Magnetic Separation Solution

Engineered for heavy-duty industrial use, these rare earth plate magnets utilize neodymium elements for exceptional magnetic strength, ensuring reliable removal of ferrous particles. Their robust stainless steel construction and polished finish make them suitable for demanding environments and extended service life. The customizable size range allows precise integration into existing lines, maximizing process efficiency while accommodating large flow rates.

Applications Across Multiple Industries

These plate magnets are commonly positioned above conveyors, chutes, or hoppers to safeguard product purity by extracting tramp metal. Industries such as food processing, mining, recycling, and pharmaceuticals benefit from their powerful, maintenance-free operation, helping to meet safety and quality standards while protecting downstream equipment from damage caused by metal contaminants.

FAQs of Rare Earth Plate Magnets:

Q: How are Rare Earth Plate Magnets installed in an industrial setting?

A: These magnets are typically positioned above conveyor belts, chutes, or hoppers using mounting brackets or frames. Installation is straightforward due to the solid rectangular plate design and requires no electrical connections, as power supply is not needed.Q: What materials can be separated using these magnets?

A: Rare Earth Plate Magnets are highly effective at capturing both fine and large ferrous contaminants, including iron filings, bolts, nails, and metal shards, from product streams. Their neodymium cores ensure strong magnetic attraction, making them suitable for a wide range of materials and bulk flow processes.Q: When should magnetic separation plate magnets be used in production processes?

A: These magnets are best utilized when your production process demands relentless removal of metal contaminants to protect equipment and ensure product quality, particularly before critical downstream processing or packaging stages.Q: Where are these magnetic plates most beneficial in industrial environments?

A: They are invaluable in food processing plants, recycling facilities, mining operations, pharmaceuticals, and any context where preventing metal contamination is critical to safety, compliance, and equipment integrity.Q: What are the benefits of using rare earth embedded plate magnets compared to standard magnets?

A: With embedded neodymium rare earth magnets, these plates provide superior magnetic force, allowing for more efficient separation of even small and weakly magnetic particles. The permanent nature also eliminates running costs and ongoing maintenance related to power supply systems.Q: How does the customizable size range add value to different applications?

A: The ability to customize plate dimensions, including widths from 100 mm to 1000 mm or more, ensures optimal coverage and magnetic separation efficiency tailored to unique conveyor or hopper specifications, enhancing both process safety and productivity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS