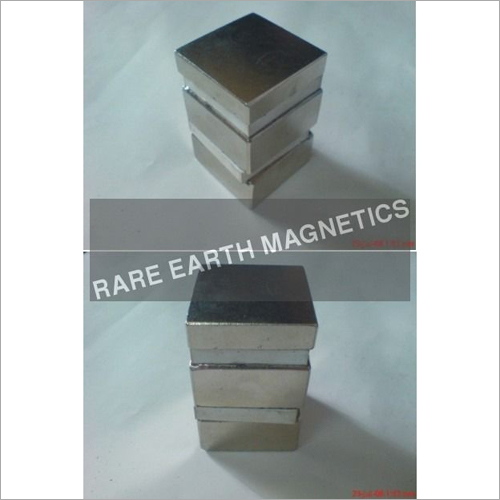

SmCo Rare Earth Magnets

SmCo Rare Earth Magnets Specification

- Application

- Industrial and scientific magnetic applications

- Magnet Grade

- SmCo5, Sm2Co17 (As per requirement)

- Material

- Samarium, Cobalt, Iron, and other trace metals

- Composite

- SmCo (Samarium Cobalt)

- Product Type

- Rare Earth Magnet

- Magnet Category

- Samarium Cobalt (SmCo)

- Magnet Type

- Permanent Rare Earth Magnet

- Shape

- Disc, Block, Ring, Arc, Customized shape

- Size Range

- Customized size available

- Weight

- Vary as per dimensions

- Color

- Metallic Grey

- Capacity

- High magnetic strength

SmCo Rare Earth Magnets Trade Information

- Payment Terms

- Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- Piece

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, South America, Western Europe, Africa, Central America, Asia

About SmCo Rare Earth Magnets

In our extensive gamut of products, we bring forth for our clients a wide assortment of SmCo Rare Earth Magnets. These magnets are widely demanded in various applications where high operating temperature and oxidation resistance are crucial. Provided magnets are designed and manufactured using superior-quality basic materials and progressive techniques in tandem with international quality standards. We offer these SmCo Rare Earth Magnets to the clients in various designs and other specifications at marginal prices.

Features:

-

Optimum magnetic performance

-

High operational temperature

-

Non-deformable magnetic performance

-

Long lasting

Versatile Magnetic Solutions

Our SmCo Rare Earth Magnets are offered in various shapes such as discs, blocks, rings, arcs, and custom designs. With customizable sizes and magnet grades suitable for different strength requirements, these magnets serve a broad range of industrial and scientific applications, ensuring versatility and reliability under extreme conditions.

Outstanding Heat and Corrosion Resistance

These magnets stand out with a Curie temperature of up to 800C and maximum operating temperatures of 250C to 350C. Their composition grants excellent resistance to oxidation and corrosion, enabling them to function reliably in challenging environments where traditional magnets might fail.

Tailored for Your Application

Whether your project needs axially or diametrically magnetized magnets, we offer tailored solutions. As a supplier, exporter, and manufacturer in India, we support customers with both standard and customized options to fit precise specifications and industry requirements.

FAQs of SmCo Rare Earth Magnets:

Q: How are SmCo Rare Earth Magnets manufactured?

A: SmCo magnets are manufactured through a process involving sintering or bonding samarium and cobalt with other trace metals. The mixture is shaped, compressed, and heated at high temperatures to achieve the desired density and magnetic properties. The final magnets can be axially or diametrically magnetized based on application requirements.Q: What makes SmCo magnets suitable for high-temperature applications?

A: SmCo magnets exhibit a Curie temperature of up to 800C and can operate reliably at temperatures between 250C and 350C without losing their magnetic strength. This makes them an ideal choice for applications where high thermal stability is essential.Q: When should SmCo magnets be preferred over other magnet types?

A: SmCo magnets are preferred when applications demand strong magnetic performance under extreme temperatures or in corrosive environments. Industries such as aerospace, defense, and scientific research often choose SmCo due to their outstanding heat resistance and durability.Q: Where can customized SmCo magnets be used?

A: Customized SmCo magnets are utilized in a variety of sectors, including sensors, motors, medical devices, and advanced scientific instruments. Their diverse size and shape options make them ideal for tailored industrial needs.Q: What is the benefit of axially versus diametrically magnetized SmCo magnets?

A: Axially magnetized magnets have magnetic poles on the flat faces, which is ideal for applications needing direct pull. Diametrically magnetized magnets have poles on the curved sides, suited for rotating or torque-based uses. The choice depends on your specific application demands.Q: How do SmCo magnets resist corrosion in demanding environments?

A: Thanks to their intrinsic material composition, SmCo magnets exhibit excellent resistance to oxidation and corrosion, even without additional coatings, making them suitable for harsh environments where exposure to moisture, chemicals, or extremes of temperature is common.Q: What customization options are available for SmCo magnets?

A: We offer SmCo magnets in various shapes like disc, block, ring, arc, and fully customized forms. Size, magnet grade (SmCo5 or Sm2Co17), and magnetization direction can be tailored according to specific industrial and scientific applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rare Earth Magnets Category

NdFeB Earth Magnets

Minimum Order Quantity : As Per Requirement Piece

Shape : Other, Ring, Block, Disc (as shown)

Capacity : High magnetic flux output

Size Range : Available from 1 mm to 100 mm (custom sizes possible)

Color : Metallic Grey/Silver

Weight : Varies by size (from a few grams to several kilograms)

Industrial Rare Earth Magnets

Minimum Order Quantity : As Per Requirement Piece

Shape : Other, Disc, Block, Ring, Cylinder, Custom

Capacity : High magnetic holding force

Size Range : Custom and Standard Sizes Available

Color : Metallic Silver / Grey

Weight : Varies as per size and model

Arc Rare Earth Magnets

Minimum Order Quantity : As Per Requirement Piece

Shape : Other, Arc

Capacity : High Magnetic Strength

Size Range : Length: 10mm to 60mm, Width: 5mm to 30mm, Thickness: 2mm to 10mm (Custom sizes available)

Color : Metallic Silver

Weight : Varies as per size (Customized available)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS