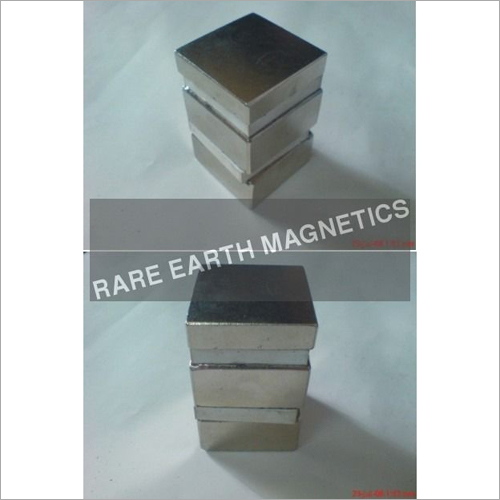

Arc Rare Earth Magnets

Arc Rare Earth Magnets Specification

- Magnet Grade

- N35, N38, N42, N45, N52 (Others on request)

- Application

- Industrial Equipment, Electric Motors, Generators, Wind Turbines, Sensors

- Surface Finish

- Nickel, Zinc or Epoxy Coated

- Product Type

- Arc Rare Earth Magnet

- Magnet Category

- Rare Earth

- Magnet Type

- Permanent Magnet

- Shape

- Arc

- Size Range

- Length: 10mm to 60mm, Width: 5mm to 30mm, Thickness: 2mm to 10mm (Custom sizes available)

- Weight

- Varies as per size (Customized available)

- Color

- Metallic Silver

- Capacity

- High Magnetic Strength

Arc Rare Earth Magnets Trade Information

- Payment Terms

- Days after Acceptance (DA), Cash Against Delivery (CAD), Cash Advance (CA)

- Supply Ability

- Piece

- Delivery Time

- Months

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Central America, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Arc Rare Earth Magnets

Arc/Segment Rare Earth MagnetsManufacturer, Exporter and Supplier of :

Various rare earth magnets and magnetic separators. We are also an importer of rare earth magnets from the markets of China, Japan and USA. Empowered with well experienced engineers, we offer an efficient line of magnetic separators in various grades such as drum type, chute type, hump type, grid type, bullet type and online liquid magnetic separators. Our portfolio of products also includes rare earth magnets like sintered NdFeB rare earth magnets, bonded NdFeB rare earth magnets, SmCo magnets, Arc/Segment rare earth magnets, etc.

Precision Engineering for Industrial Performance

Our Arc Rare Earth Magnets are precisely crafted to provide superior performance in demanding industrial environments. Engineered in arc shapes, they optimize efficiency in electric motors, wind turbines, and generators. Custom sizes and grades are available to match technical specifications, ensuring both versatility and optimal power delivery for your applications.

Versatile Applications Across Industries

These magnets are utilized widely in electric motors, generators, wind turbines, and sensors due to their exceptional magnetic strength and reliability. With a variety of coatings such as nickel, zinc, or epoxy, they offer excellent corrosion resistance, making them suitable for use in both indoor and challenging outdoor conditions.

FAQs of Arc Rare Earth Magnets:

Q: How are Arc Rare Earth Magnets used in industrial equipment and motors?

A: Arc Rare Earth Magnets are primarily integrated into electric motors, generators, and wind turbines, where their unique curved (arc) shape ensures even magnetic distribution. This optimizes torque and efficiency, making them vital for high-performance machinery in various industrial applications.Q: What sizes and customization options are available for these magnets?

A: We provide Arc Rare Earth Magnets in lengths from 10mm to 60mm, widths from 5mm to 30mm, and thicknesses from 2mm to 10mm. Custom sizes and shapes can be manufactured to meet specific design parameters for your application.Q: When should you consider using high-grade magnets such as N52?

A: High-grade magnets like N52 should be selected when applications demand maximum magnetic strength, such as in high-efficiency or compact devices where space and performance are critical factors.Q: Where are these magnets typically installed or applied?

A: These magnets are commonly installed in the motor assemblies of industrial equipment, wind turbines, electrical generators, and sensitive sensing devices, due to their high magnetic force and reliability.Q: What is the manufacturing process for Arc Rare Earth Magnets?

A: Arc Rare Earth Magnets are produced using advanced sintering and machining processes. The rare earth material is shaped, coated (nickel, zinc, or epoxy), and magnetized to the required grade before precision finishing and quality inspection.Q: How do different surface coatings benefit these magnets?

A: Surface coatings, such as nickel, zinc, or epoxy, provide significant protection against corrosion, abrasion, and chemical exposure, enhancing the durability of the magnets in various industrial environments.Q: What are the main advantages of using rare earth permanent magnets in industrial applications?

A: Rare earth permanent magnets offer high magnetic strength, excellent stability, and compact sizing, making them ideal for advanced industrial applications demanding both performance and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rare Earth Magnets Category

NdFeB Earth Magnets

Minimum Order Quantity : As Per Requirement Piece

Color : Metallic Grey/Silver

Composite : Neodymium Iron Boron (NdFeB)

Application : Industrial, Electronic Devices, Motors, Generators, Sensors

Capacity : High magnetic flux output

Magnet Category : Other, Rare Earth Magnet

Industrial Rare Earth Magnets

Minimum Order Quantity : As Per Requirement Piece

Color : Metallic Silver / Grey

Composite : Solid Magnet

Application : Industrial Separation, Lifting, Holding, Magnetic Filtration, Sensors, Motors

Capacity : High magnetic holding force

Magnet Category : Other, Industrial Magnet

SmCo Rare Earth Magnets

Minimum Order Quantity : As Per Requirement Piece

Color : Metallic Grey

Composite : SmCo (Samarium Cobalt)

Application : Industrial and scientific magnetic applications

Capacity : High magnetic strength

Magnet Category : Other, Samarium Cobalt (SmCo)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS